About Acorn Bioenergy

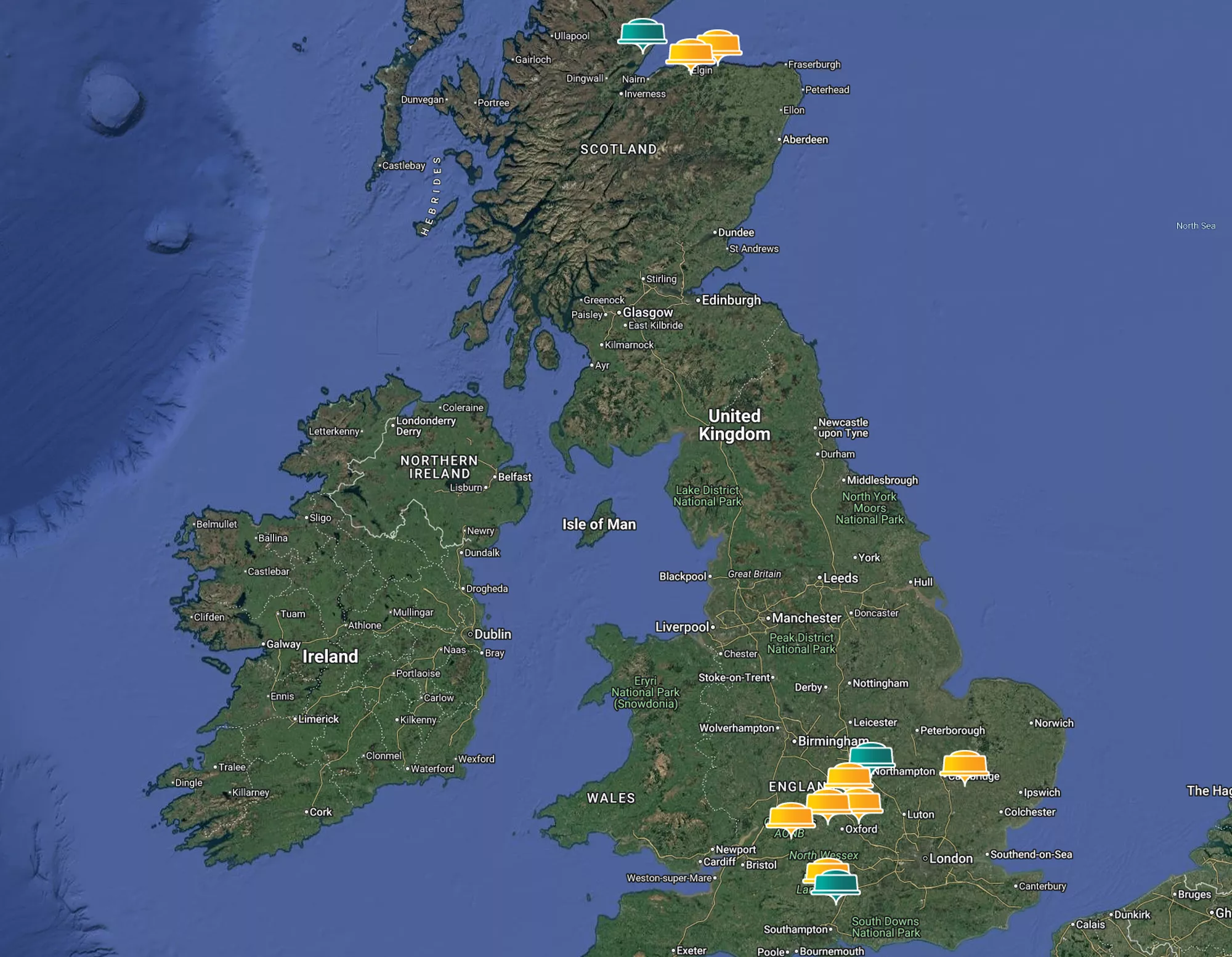

Acorn Bioenergy is a UK-based renewable energy company specialising in biomethane production through anaerobic digestion. By working closely with local farmers, Acorn turns organic waste into clean energy and useful by-products such as bio-fertiliser and green CO₂. This approach supports sustainable agriculture, drives rural economic development, and advances the circular economy. With several sites under development across the UK, Acorn is committed to creating long-term value for local communities and contributing to a more resilient and prosperous future.

Read more →